Learn how to make candles - summary

Basic materials for candle making.

The following basic materials are needed to make even the simplest candle.

Casting molds that can withstand a maximum temperature of 100°, paraffin, wicks, dyes, odors, etc.

--------------------------------------------------------------------------------------

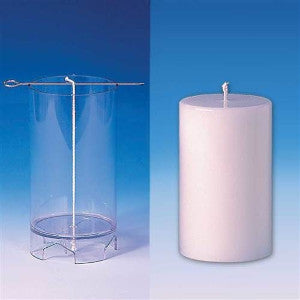

Preparation of the mold.

Proceed as follows (photos to follow):

1 Use a sturdy, thick needle that can be guided through the mold (at the bottom).

2. Insert the appropriate wick for the candle to be cast through the needle. (See below for wick thickness.) Place the seal of the candle mold over the needle and guide the seal along the wick so that everything (casting mold, wick, and needle at the top) is neatly stretched. After the needle with the wick has been inserted through the opening at the bottom of the mold, the wick can be secured at the top of the mold to a needle or other sturdy material. (I use metal rods or needles.)

After everything is securely fastened (wick, wick holder, etc.), the shape at the bottom where the end of the wick is located can be cut off.

Always ensure the wick is straight and not twisted in the mold. A twisted wick can cause erratic burning.

Always use flat blades (reinforced) instead of round blades. When using only stearin, round blades are recommended.

Preparing to pour into glass molds.

1. Use our high-neck wick foot . Thread the wick through the wick foot.

2 Pinch the neck of the wick foot closed so that the wick does not come loose.

3 Hang the wick with aneedle or wooden stick (e.g. satay stick).

4. Use our paraffin for glass . This paraffin adheres better to glass or other materials such as pottery, plastic, etc.

5 Heat the paraffin for glass, without adding stearine, to 68° C.

6 Only add dye and/or fragrance at the end, when the paraffin has reached the correct temperature.

7. Slowly pour the paraffin into the mold and guide the wick with the wick base towards the center of the candle mold.

Paraffin wax for glass has the characteristic of low shrinkage. After the paraffin has hardened, a single application is sufficient.

Preparing dipped candles (table candles)

Table candles are dipped to achieve the desired thickness, layer by layer. This form of candlemaking cannot be molded, but it can be pressed, unlike cheaper products available on the market.

How to proceed?

1 use the thinnest wick (3x7)

Dipping is done with a holder over which the wick is placed, and this is done with holders of 6 or more candles. With this type of candle, make sure the wick is straight and not twisted.

3. Dipping is done in a pot high enough to achieve the desired candle length. An ideal temperature is 71°C, as low as possible because it's necessary to wait between each dip to allow the previous layer to harden. Once dipping begins, the entire process must be completed, otherwise layers will form that can separate from each other.

4 Dipping is approximately 15 to 30 times depending on the desired thickness of the table candle.

5 The final immersion is best done at 85°C to obtain a smooth surface.

Tip: Let the dipped candles harden for a few hours. If the candles haven't hardened, they will warp when removed from the holder due to the shrinkage of the paraffin.

Ratios of stearin and paraffin

With candle remains

If you're making your first candles, you'll likely use candle scraps you had yourself or received. Because we don't always know the composition of candle scraps that aren't homemade, I recommend using the following ratios. It's also crucial to thoroughly clean the candle scraps first. Melt the candle scraps and pour them through a fine-mesh metal sieve, forming a single sheet of tissue paper into the sieve to remove any impurities and old wicks.

50% candle residue

50% new paraffin

10% stearin = of the ratio of candle residues/paraffin.

Paraffin candle.

When making candles with new paraffin, the ratio is:

85% to 90% good quality paraffin

15% to 10% good quality stearine

If you use more stearin, the paraffin will burn faster than the stearin, resulting in the wick becoming too small and the candle going out.

Wick thickness

There are mainly two types of wicks: flat and round. I exclusively use flat wicks, which are also reinforced. The reason flat wicks are used is mainly for paraffin candles. Stearic candles are more suited to round wicks.

What thicknesses are available for wicks and their corresponding burn circle?

Candle Diameter Wick Description

Indoor candles

1 1cm to 4cm (3x6)

2 4cm to 6cm (3x8)

3 6cm to 8cm (3x10)

4 8cm to 10cm (3x12)

5 10cm to 12cm (3x18)

Outdoor candles

1 10cm to 20cm (5mm)

2 12cm to 22cm (7mm)

3 15cm to 25cm (9mm)

4 20cm to 30cm (12mm)

--------------------------------------------------------------------------

Preparing the mold

Preparing the molds for casting.

1. First, the stearin must be liquefied in the melting pot. The stearin will have a watery appearance once fully melted.

2. A dye can be added to the stearin during the melting process. Adding the dye should be done before adding the paraffin.

3. Add paraffin in the correct proportion to the already melted mixture. (See point 3 - Preparing the mold.)

Temperatures used in casting.

There are various temperatures that can be used when pouring candles. It all depends on the desired appearance and result.

Paraffin melts at 56°C and catches fire at 180°C

To achieve a smooth candle structure (when using plastic molds), the temperature should be between 80°C and 90°C. The difference between these two temperatures depends on the environment where you make candles or the season. A candle will set more slowly in summer than in winter. I personally use 76°C to 78°C at a stable temperature in my studio. A colleague pours even at a lower temperature for the same result, namely 72°C.

If you have used too low a temperature but still want a shiny candle without having to melt the candle, you can always use a dipping varnish.

At temperatures below 71°C (160°F), the candle will have a marbled appearance. However, you will then need to clean the mold more often. This method of using lower temperatures is also called cold casting. For a more even appearance, it's better to use marble wax.

If the paraffin mixture has exceeded 100°C, this mixture can only be used for making outdoor candles.

USE YOUR THERMOMETER CONSTANTLY!! to maintain a constant pouring temperature.